Plan

Contents

Filtering plans

All plans

My plans

By plan type

By status

As calendar

Closed plans

Obsolete plans

My plans (responsible)

My plans (worker)

New Maintenance plan

General

Asset information

Plan information

What was done

New Calibration plan

Calibration result

Proper planning and scheduling should be a key initiative within every organization. This is particularly valuable when it comes to the maintenance and calibration of company assets and equipment. To successfully maximize the life of your assets, while minimizing upkeep costs, you need to come up with an efficient maintenance plan. CCQ enables you to develop and implement effective planning and scheduling programs that improve asset performance and reliability.

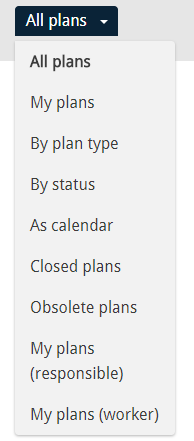

Filtering plans

When you’re inside the Plan interface, you can select different views by filtering out the asset maintenance plans that you want to inspect. There’s a drop-down list with different filtering options at the top of the interface. The maintenance plans then appear in a list below, in accordance with the selected filter. The following are descriptions of the filter options available in the Plan module.

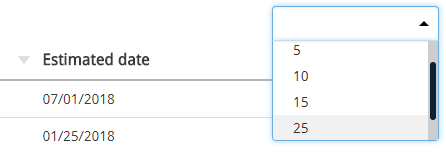

All plans

When All plans are selected, you obviously get an overview of all maintenance/calibration plans in the system – closed plans excluded. You can control how many documents are shown on the page you’re viewing, via a drop-down list on the top-right side. The options you’re given are 5, 10, 15, 25 or simply all documents.

My plans

When My plans are selected, you get an overview of all maintenance/calibration plans that you are personally responsible for. Meaning that you explicitly have to be the plan’s Responsible person – this filter will not pick up on plans where you are only the appointed Worker.

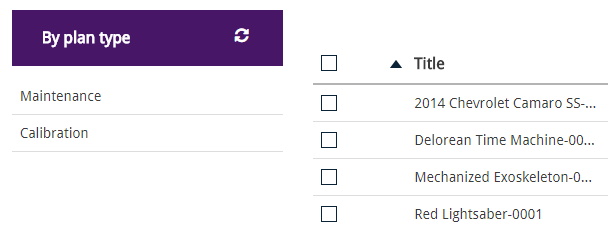

By plan type

If you’re interested in finding plans of a particular type, you can use this filter. When this filter is selected, an additional filter comes into sight on the left side of the document list where you can choose between the two plan types that are defined in the system – either maintenance or calibration.

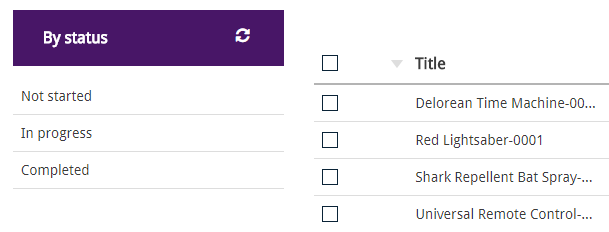

By status

The status of plans is indicated in three ways in the system, i.e. Not started, In progress, or Completed. When you filter By status, you get another filter where you can find plans on different status levels.

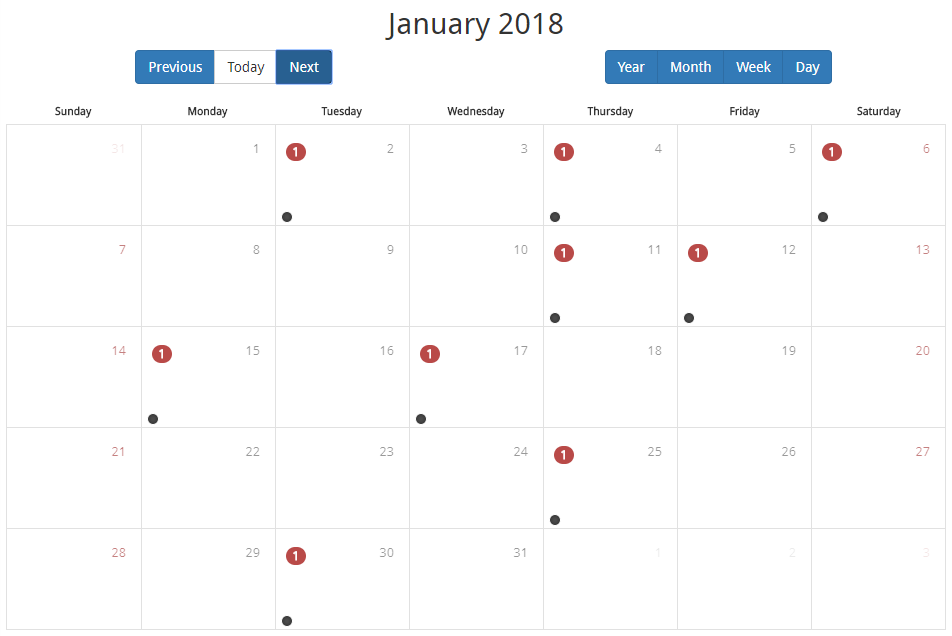

As calendar

When you filter maintenance and calibration plans by As calendar, you get a calendar where you can find plans that are due to be performed on different dates. You can scan through the calendar by year, month, week or day. Scheduled maintenance/calibration plans are indicated with dots on their respective calendar dates.

Closed plans

If you’re interested in reviewing old maintenance or calibration plans and how they were resolved, you can use this filter to retrieve a list of all Closed plans.

Obsolete plans

Obsolete plans are basically older versions of maintenance/calibration plans that have been deleted. With this filter, you can find every plan that has become obsolete. Note that you won’t find the newest version of the plan here, you’ll have to look for that in the Recycle bin.

My plans (responsible)

This is basically the same filter as My plans.

When My plans (responsible) are selected, you get an overview of all maintenance/calibration plans that you are personally responsible for. Meaning that you explicitly have to be the plan’s Responsible person – this filter will not pick up on plans where you are only the appointed Worker.

My plans (worker)

When My plans (worker) are selected, you get an overview of all maintenance/calibration plans that you are personally working on. Meaning that you explicitly have to be the plan’s appointed Worker – being personally responsible for the plan has no effect on this filter.

New Maintenance plan

The importance of regular asset maintenance cannot be overstated.

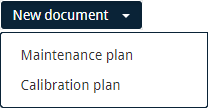

If you mark the Should maintain checkbox in an asset and Save it, a maintenance plan is automatically created for that asset. Another way to create a maintenance plan is to simply click the New document dropdown in the top-right corner of the Plan interface, and select Maintenance plan.

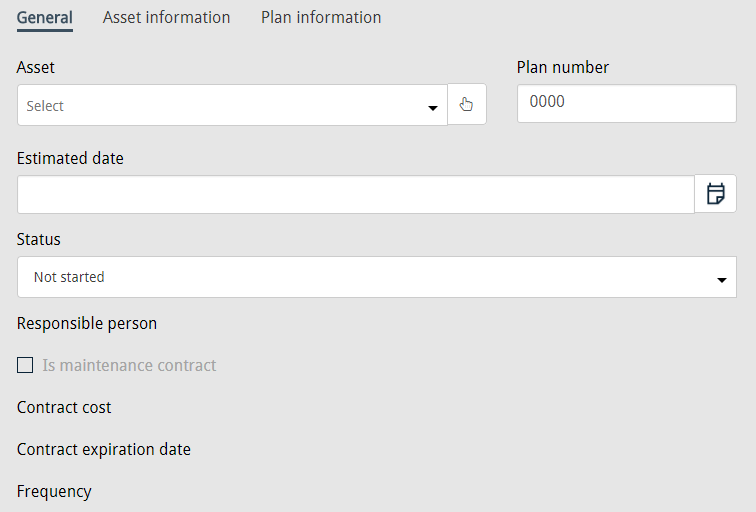

General

In the General tab, the basic information of the maintenance plan is listed. Understandably, the Asset field is required – there’s no maintenance plan without an asset. When the maintenance plan is created, the CCQ system automatically assigns it a number. The number depends on whether there have been any previous plans made for this particular asset, or not. Every maintenance plan should have a deadline, and you should try to give an estimate for when the maintenance should be completed. Finally, you can set the status of the maintenance plan to Not started, In progress, or Completed.

The details listed below the Status field reveal information already registered in the corresponding asset document. Records on the person that’s responsible for the asset, whether there’s a maintenance contract, its cost and expiration date, and the frequency of inspection/maintenance, are shown here. Note that the data doesn’t appear until the maintenance plan is Saved, and it cannot be altered. If you want to change anything, you have to find the corresponding document in the Asset interface, and change it there.

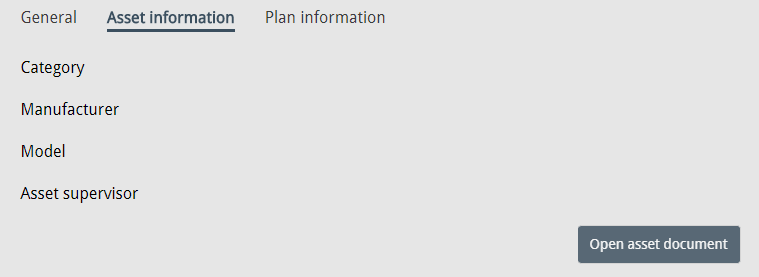

Asset information

The details listed in the Asset information tab reveal information already registered in the corresponding asset document. The fields that are listed are Category, Manufacturer, Model, and Asset supervisor. If you want to change any of this information, you’re not able to that here – you have to do it in the Asset interface.

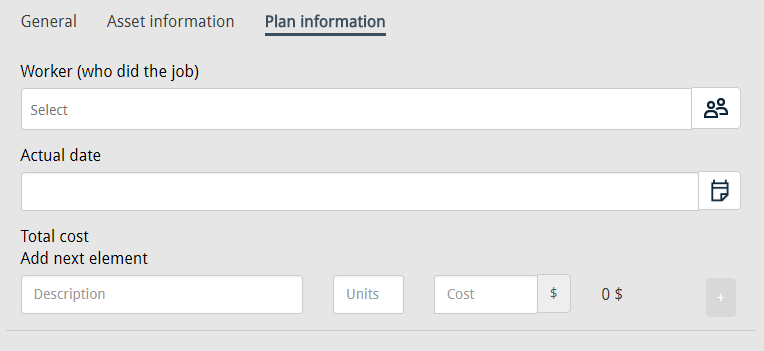

Plan information

The Plan information tab contains information on the individual that performed the actual maintenance, and the date on which it was completed. A useful feature allows you to estimate the resulting costs – no matter whether they are direct or indirect. A brief description of the cost items is registered, as well as the number of units and estimated cost of each item. For example, you can determine the hours of work spent on the resolution of an incident, enter the employee’s hourly wage, and the system will calculate the estimated cost. If there are any more cost items, you can add them by clicking the plus button on the right-hand side, and the system computes the total sum.

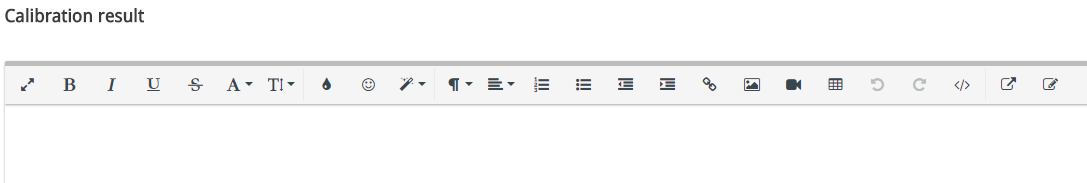

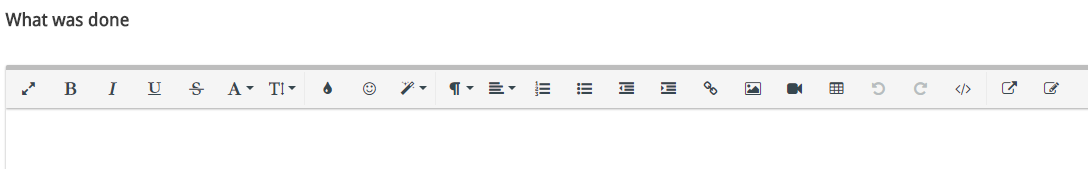

What was done

The built-in text editor below, allows you to give a more detailed description of what was done in the asset maintenance.

New Calibration plan

The importance of regular equipment calibration cannot be overstated.

If you mark the Should calibrate checkbox in an asset and Save it, a calibration plan is automatically created for that asset. Another way to create a calibration plan is to simply click the New document dropdown in the top-right corner of the Plan interface, and select Calibration plan.

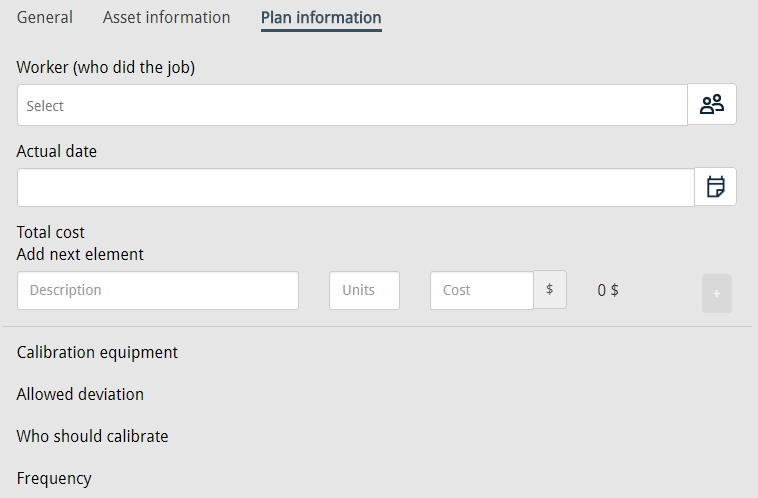

The template for a new calibration plan is very similar to the one for maintenance plans. The difference is in the details listed below the Status field in the General tab – they are not as many as for maintenance plans. In Plan information, under the Total cost calculator, you get additional info on the calibration equipment, allowed deviation, who should perform the calibration, and the frequency of service. This data reveals information already registered in the corresponding asset document as well, and cannot be altered unless you look up the document itself in the Asset interface.

Calibration result

The built-in text editor below, allows you to give a more detailed description of the calibration result.